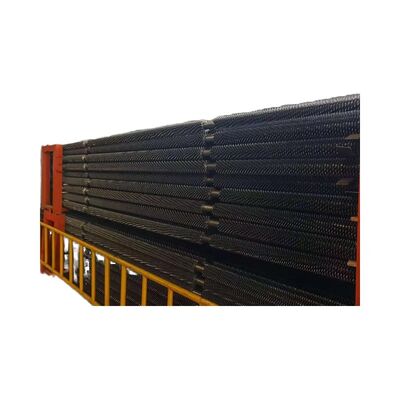

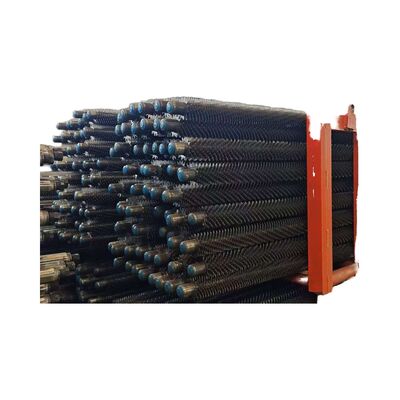

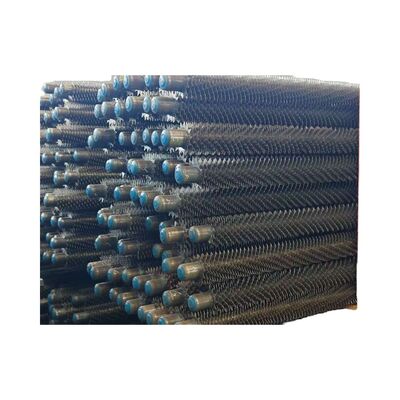

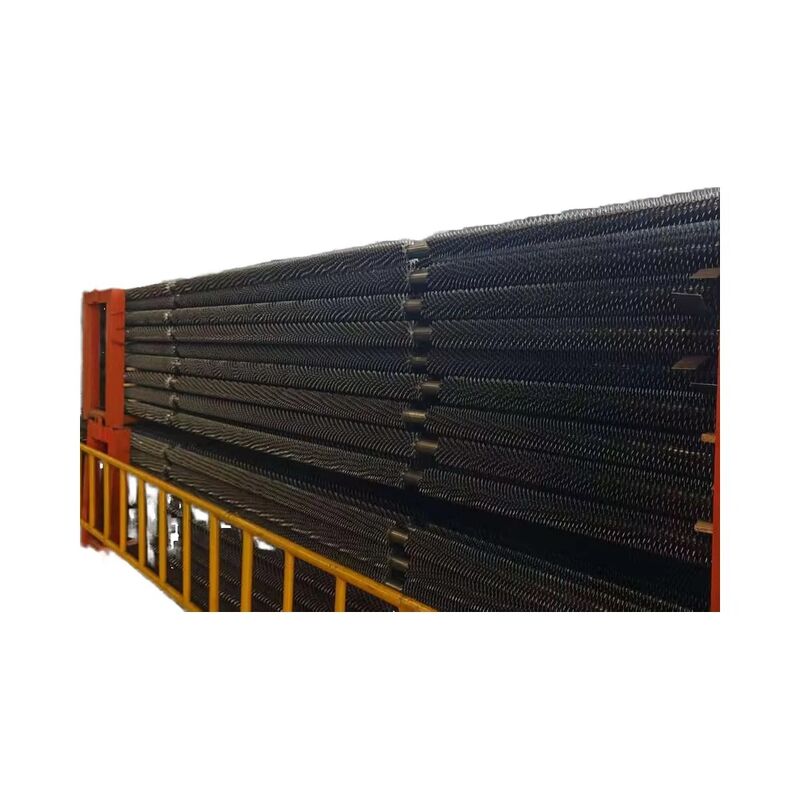

Customized Spiral H Fin Tube Energy Saving Boiler Parts

Product Specifications

| Item |

Base Tube O.D (mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin Thickness (mm) |

Fin Pitch (mm) |

| Range |

25.4 ~ 1600mm |

2.5 ~ 40mm |

0.5 ~ 20.0mm |

0.5 ~ 3.0mm |

5 ~ 25.4mm |

| Material |

Carbon Steel, Alloy Steel, Stainless Steel |

| Length |

0 < L < 12000mm |

H-Fin Tube Details

| Product |

H-fin Tube |

| Base Pipe |

Welded or Seamless |

| Material |

Carbon steel, alloy steel, stainless steel, non-ferrous alloys and nickel alloys |

| Application |

H economizer, H evaporator, H superheater, H air heater and related systems |

Product Introduction

Boiler economizers are heat exchange devices with finned tubes that heat liquids, typically water, up to but not exceeding the boiling point. We manufacture three types of boiler economizers: bare tube economizer, H finned tube economizer, and spiral finned tube economizer.

The H-finned tube economizer is a highly efficient heat exchanger consisting of H-finned tubes. Compared with bare tube economizers, H-finned tube economizers can significantly enlarge the heat exchange area while reducing the number of tubes required. This design also increases flue gas flow area to reduce flow speed and minimize abrasion.

H-finned tubes can be manufactured as double H finned tubes with high rigidity to accommodate long tube rows. The spiral finned economizer is a newly designed heat transfer equipment that utilizes spiral fin tubes to overcome serious abrasion issues and extend service life.

Function & Benefits

The primary function of the economizer is to "economize" or save on cooling costs. By enabling compressor shutdown while maintaining adequate cooling capacity, significant energy savings can be achieved.

Boiler Economizer Parameters

| Description |

Boiler economizer |

| Material |

Alloy steel, Carbon steel, SA210C, SA213T22, etc. |

| Material Standard |

ASTM, EN or ISO etc. |

| Dimension |

Customization |

| Weight |

Min: 10 ton, Max: 1000 ton |

| Smelting Process |

EF+LF+VD |

| Process |

Material→Ingot→Hot/Cold-Rolling→Heat treatment (Normalizing+tempering)→Inspection→Rough machining→UT→2nd Heat treatment→Finishing machining→Inspection |

| UT Standard |

ASTM A388 or EN10228, etc. |

Company Profile

Zhangjiagang Hua Dong Boiler Co., Ltd., founded in 1985, is an enterprise specializing in manufacturing power station boilers, industrial boilers, HRSGs, waste incineration boilers, biomass boilers and related heating surface components in China. Hua Dong Boiler provides clients with integrated services from design, manufacturing to installation and maintenance.

Our Advantages

38 years experience in industry research, development and manufacturing with sufficient production capacity.

Quality Control

- Impact test and Strength calculation report with applied materials information

- 100% NDT (non-destructive inspection) report of steel plate, tube and electrode

- X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler

- Hydraulic test report: ensure the standard working pressure and safety

Complete quality assurance and control system certified according to International Quality Standards. We establish a quality assurance system in compliance with national regulations, standards and technical requirements. All processes and products are 100% under control, ensuring manufacturing according to contract requirements, national regulations and standards through stringent inspection and testing.

Certifications

Owns verification certificates:

ISO 9001: 2015; CE certificate; EN ISO 3834-2; ASME certificate with "S", "U" and "NB" stamps, etc.

Frequently Asked Questions

Q1: How long is the warranty period?

We provide 18 months warranty for all spare parts (excluding fragile parts).

Q2: How can we guarantee quality?

- All machines are in strict accordance with ISO quality and CE system requirements

- Each procedure is crafted by professional skilled labor, followed by particular QC

- All information of our products can be checked in efficient management system

Q3: What can you buy from us?

CFB Boiler, HRSG Boiler, Boiler Economizer, Boiler Fin tube, Boiler Air preheater, Boiler superheater, Boiler membrane wall, Boiler manifold headers and other pressure spare parts.

Q4: What kind of service do you provide?

Before sales: Provide product information, market research forecasting, product customization, product processing, consultation and other services for your convenience.

After sales:

- Technical training according to customer requirements

- We promise replacement under warranty

- We promise to supply maintenance spare parts

- Regular call back or visit customers

- On time response to mail and phone calls of your complaints or consultation

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FCA

Accepted Payment Currency: USD, CNY

Accepted Payment Type: T/T, L/C, MoneyGram, Western Union, Cash

Language Spoken: English, Chinese

Q5: Are you a factory or trading company, where are you located?

We are a factory, just 130km (2 hours by car) away from Shanghai Airport. We offer pickup service at Shanghai for your visit.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!